Torque Ratings

7th May 2020

"How do I choose the DYNAMIXEL with enough torque for my application?"

ROBOTIS produces a wide range of DYNAMIXEL models with different features, sizes, and torque specifications. A common question from users is “How do I know which model has enough torque for my application?”. To find the answer, let’s take a look at how torque is applied in a robotic system:

Torque in robotic systems is used to describe the amount of force applied in a circle, in this case the output horn of the DYNAMIXEL or servo. To determine whether the torque of your DYNAMIXEL is sufficient for a motion, the Torque must be equal to or greater than the forces that the servo will be overcoming in your system.

Before choosing your size of DYNAMIXEL, calculate the estimated torque requirements of your motions. A basic reference diagram is shown here:

Understanding Torque Specifications- Stall vs. Continuous

The Torque specification of DYNAMIXEL models is generally rated in one of two ways: Stall Torque or Continuous Torque.

Continuous Torque: A Continuous Torque rating is the estimated torque the unit is able to output while being run constantly. Continuous Torque does not represent the full Torque output, however it is recommended to plan motions within the Continuous Torque range of a model.

Stall Torque: The maximum peak torque output capable by the unit, at which point the output speed drops to zero (stalled). Stall Torque is also accompanied by the maximum current draw specification. It is not recommended to attempt to use Stall Torque for extended periods of time, or to plan to use a unit at its Stall Torque rating continuously. Due to the excessive current drawn by the motor, running a servo at the full Stall Torque rating often may cause damage due to heat of the motor, or other issues. Models rated in Stall Torque can have their continuous torque estimated using the formula:

Continuous Torque = Stall Torque * 0.20

N-T Curves

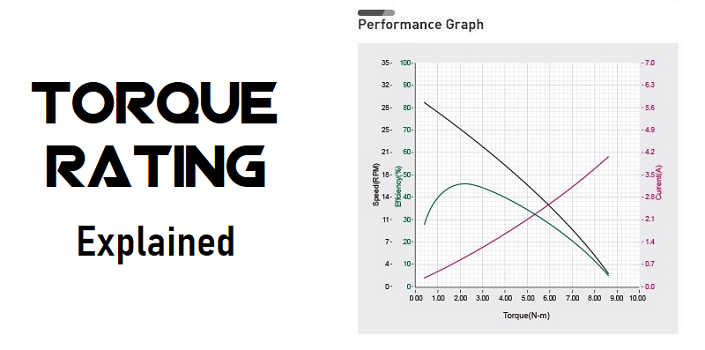

Every DYNAMIXEL has a chart showing the torque, speed, and efficiency of the unit at various points, known as an N-T curve, available in the product e-Manual. Take a look at this example- the Stall Torque is the point at which the black line (Speed- RPM) would drop to zero. (It’s hard to move with zero speed!)

The earlier range of the graph represents the Continuous Torque, where the unit runs with higher speed and efficiency (but less total torque). The higher efficiency and decreased load mean less wear on the hardware, and make Continuous Torque a better specification to plan a system using.

Remember:

- To know what power/size of DYNAMIXEL you need, estimate the Torque needed for your motions

- Models can be rated in Stall Torque or Continuous Torque- check the specification to see which it is. You want to compare a continuous torque specification to your estimated calculations.

- For models rated in Stall Torque: Continuous Torque is estimated as 20% of the Stall Torque, or Continuous Torque = Stall Torque * 0.20

- Keeping your robot’s motions within a safe torque range can help to ensure your system or installation reaches its maximum potential!